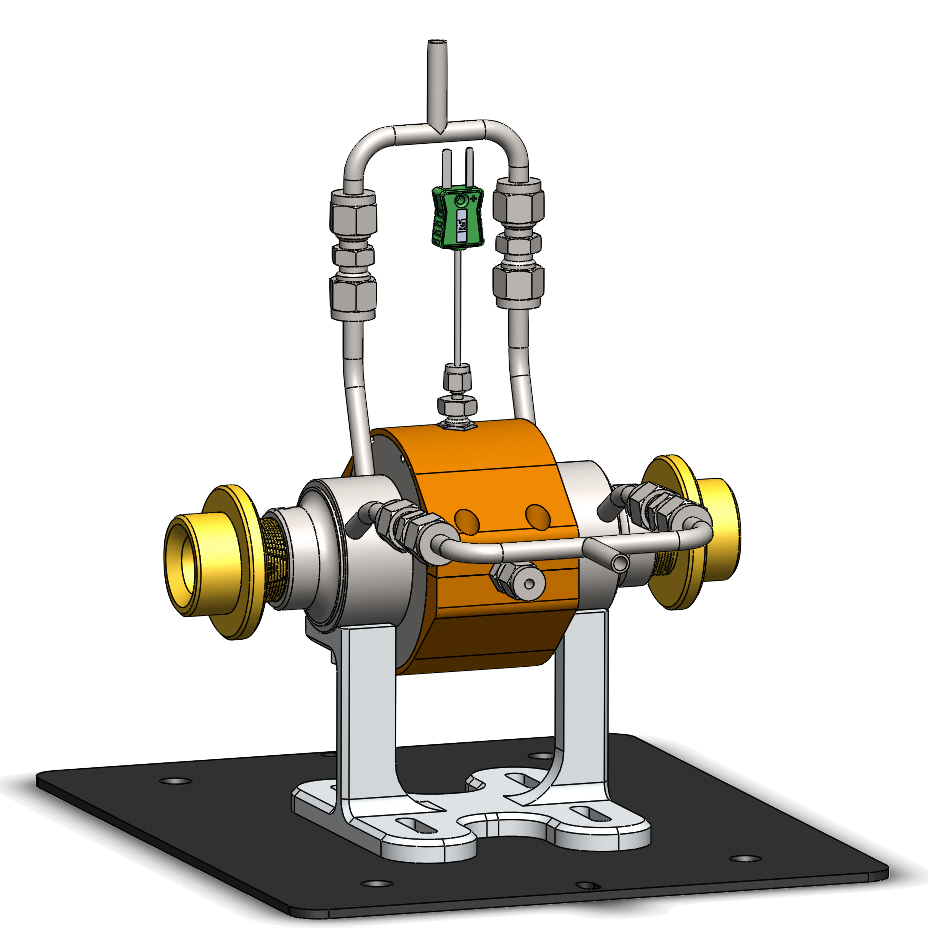

An operando FTIR reactor for studying materials and reaction mechanisms in real operating conditions.

Characteristics

Real-time conditions

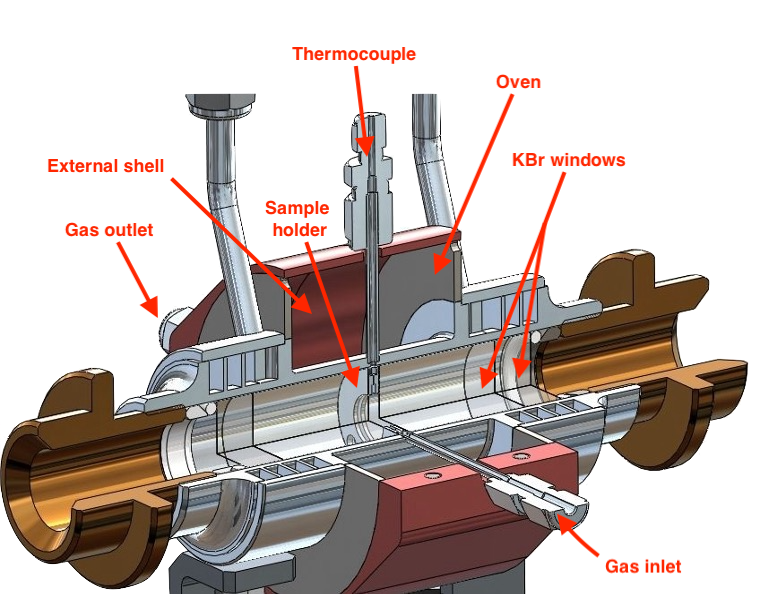

Analysis of the gas and the surface phase using FTIR in real-time conditions to identify the nature of the reacted, intermediate and formed species.

Controlled flow

Analysis in operando conditions: conditions in which the process conditions (flow composition, temperature and pressure) are controlled to be close to the reality.

Features

- Cell body made of stainless steel (inox 316 L or inconel)

- Dimension: suitable for the compartment of an IR spectrometer

- Small internal volume (~ 0.5 cm³)

- Gas flow : 5-100 cm³/min

- Temperature: ambient temperature to 500 °C (under flow)

- Working pressure: atmospheric pressure to 10 bars

- 110 V power supply

- Air cooling system (Compressed air, not provided)

- Self-supported wafer (diameter = 16 mm)

- Swagelok fittings: 1/4 » (cooling), 1/8 » (gas inlet/outlet), and 1/16 » (thermocouple)

Accessories

- 3 valve glass fitting (glass-metal) for precise addition of probe molecules

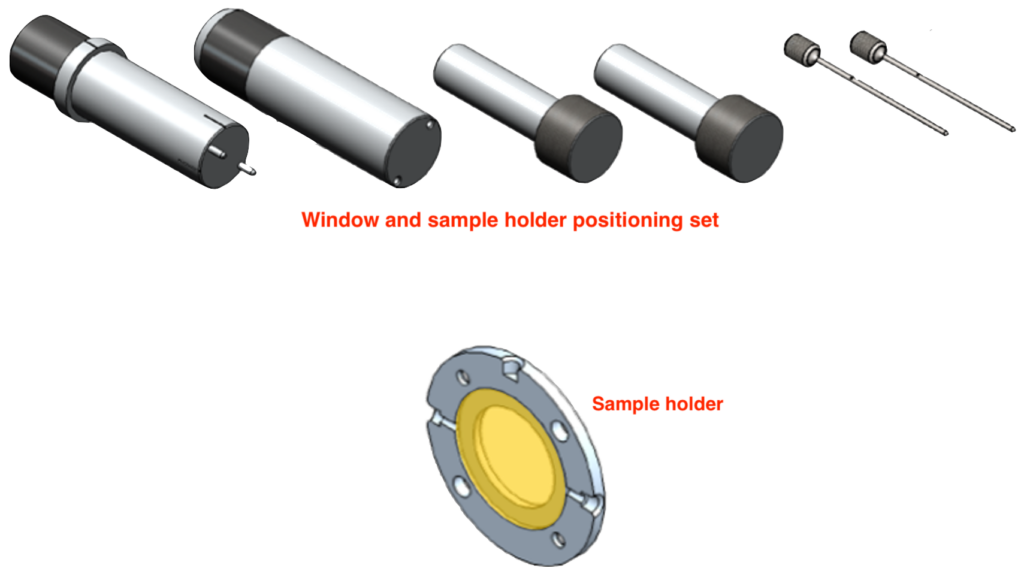

- Sample holder for a 16 mm disc wafer or a square wafer: 11 x 11 mm

- KBr, CaF₂ or BaF₂ windows (25 x 12 mm and 25 x 32 mm)

- Viton gaskets for better sealing

- K type thermocouples

- Temperature controller: 220 V power supply

- Sample holder and window positioning set

Applications

- Study of the reaction mechanism

- Adsorption of molecules, separation of pollutants…

- Molecular-scale study of the thermal stability of materials

- Determination of the intermediate species

Additional ressources:

Discovering the active sites for C3 separation in MIL-100(Fe) by using Operando IR Spectroscopy